Projects

Last Updated: 01/08/2025

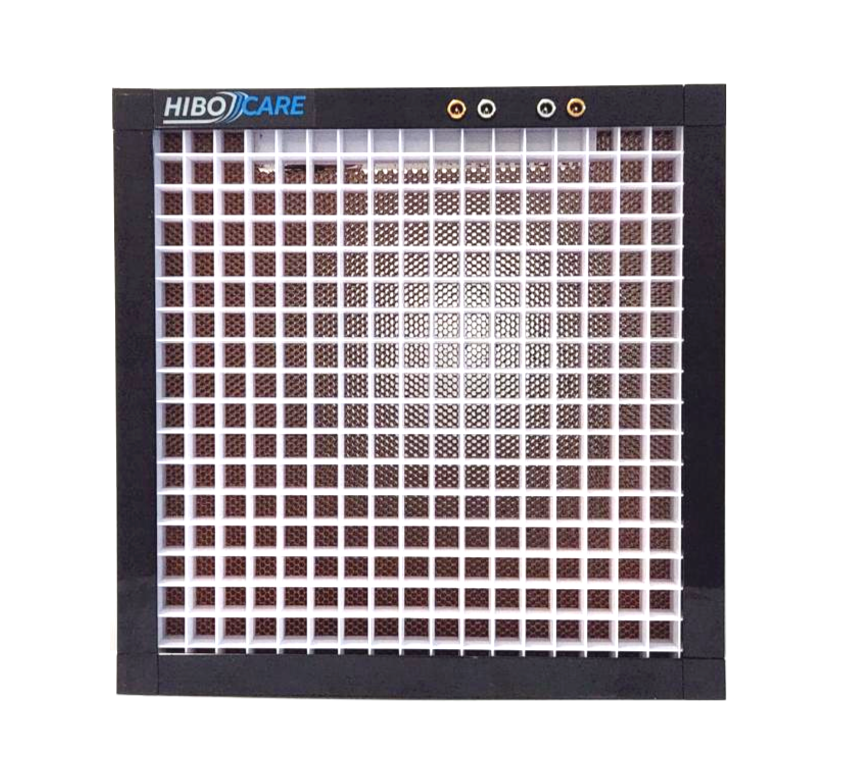

HiboScreen™

HiboScreen™ is a breakthrough air-cleaning solution that boosts HVAC efficiency while neutralizing viruses, bacteria, and mould. Easy to retrofit and energy-saving, it delivers healthier indoor air in a greener, more cost-effective way.

Currently working on the next generation of the active air-filtration screen. Co-Inventor in the latest patent which optimizes the build to reduce size, power consumption and cost.

Recycling Automation Machine

Collaborated with Vitasoy Hong Kong to automate a particular step of the recycling process of Tetrapak.

The MVP has been developed while keeping a good balance between functionality, cost and speed. It is currently under testing. The product will be an ongoing R&D project which will then be productized for consumer usage.

Multi-Tool 3D Printer

Internal R&D project for a novel 3D printer. Tailor-made printer with multiple, detachable tools which can extrude proprietary material. It is currently used as a platform for internal testing.

Wine Celler

I worked on a prototype of a smart wine cellar tailored for wine connoisseurs to store specialty wine at specific temperature. It was designed with both aesthetics and functionality in mind. It included an array of sensors to incorporate several unique features and there is also a screen present to display the status of each compartment.

Orthopedic Implant

A patent-pending implant for the fixation of bone fragmentation in the proximal humerus.

Patent

Water bath

A temperature-controlled water-bath used to run material testing of implants submerged in fluids at body temperature to mimic in vivo conditions. A controller with a temperature sensor was used to regulate the temperature.

Screw Pull-out Jigs

Fixtures, made of SUS316, designed as per different dimensions of the screw head of different screws to perform screw Pull-out experiments.

Suture Testing Jig

Testing jigs designed to perform tensile tests on different sutures without causing excessive stress concentration on specific regions. This was achieved using large curvature with minimal sharp edges for looping and attaching the suture.

Bending Jigs

Adjustable bending jigs designed to perform either 3-point or 4-point bending tests on Orthopedic Screws. Hardened SUS420 was used to ensure the jigs don’t get damaged. Cylinders of different sizes could be used to do tests on screws of different specifications.

Suture Retreiver

An ergonomic hand-held tool that helps surgeons retrieve sutures while performing Proximal Humerus Fracture fixations. The design of the tip allows it to be inserted through a small incision and the contact surface sits flush on proximal humeri of different sizes.

Custom Screw-driver

Custom Screw-Driver made to fit screw heads with minimum tolerance to perform torque test. The image shown is a driver made to lock into the Multiloc Screw head perfectly. Hardened SUS420 was used to manufacture the driver.

Custom Screw Clamps and Collets

Screw clamps designed according to different screw specification which allow users to clamp on to screws without damaging the threads. The fixture could be used to perform torque test on screws so hardened SUS420 was used to ensure the fixture is not damaged.

Alfonso™

A proprietary implant testing service trusted by leading medical device companies, delivering highly accurate bone and implant simulations up to 10× faster than traditional labs to cut costs, speed design, and ensure safer implants.

Helped validate and troubleshoot source code by rigorous testing.

Validation Papers

Fluid Dispenser

A dispenser made from a deconstructed pipette and a stepper-motor. Most of the fixture for the device was manufactured using 3D printed PLA. A pipette tip holder was integrated with a robot arm which was then connected to the pipette using a plastic tube. It was fine-tuned such that any volume of fluid (within the max limit) could be retrieved and dispensed automatically.

Modular Cartridge

A cartridge, made of 3D printed PLA, designed to hold multiple test-tubes containing different fluids. The top tray of the cartridge could be removed to place the test-tubes and the acrylic cover on top prevented contamination. A servo-motor was attached to the top cover (with a single hole) to only provide access to specific test tubes.

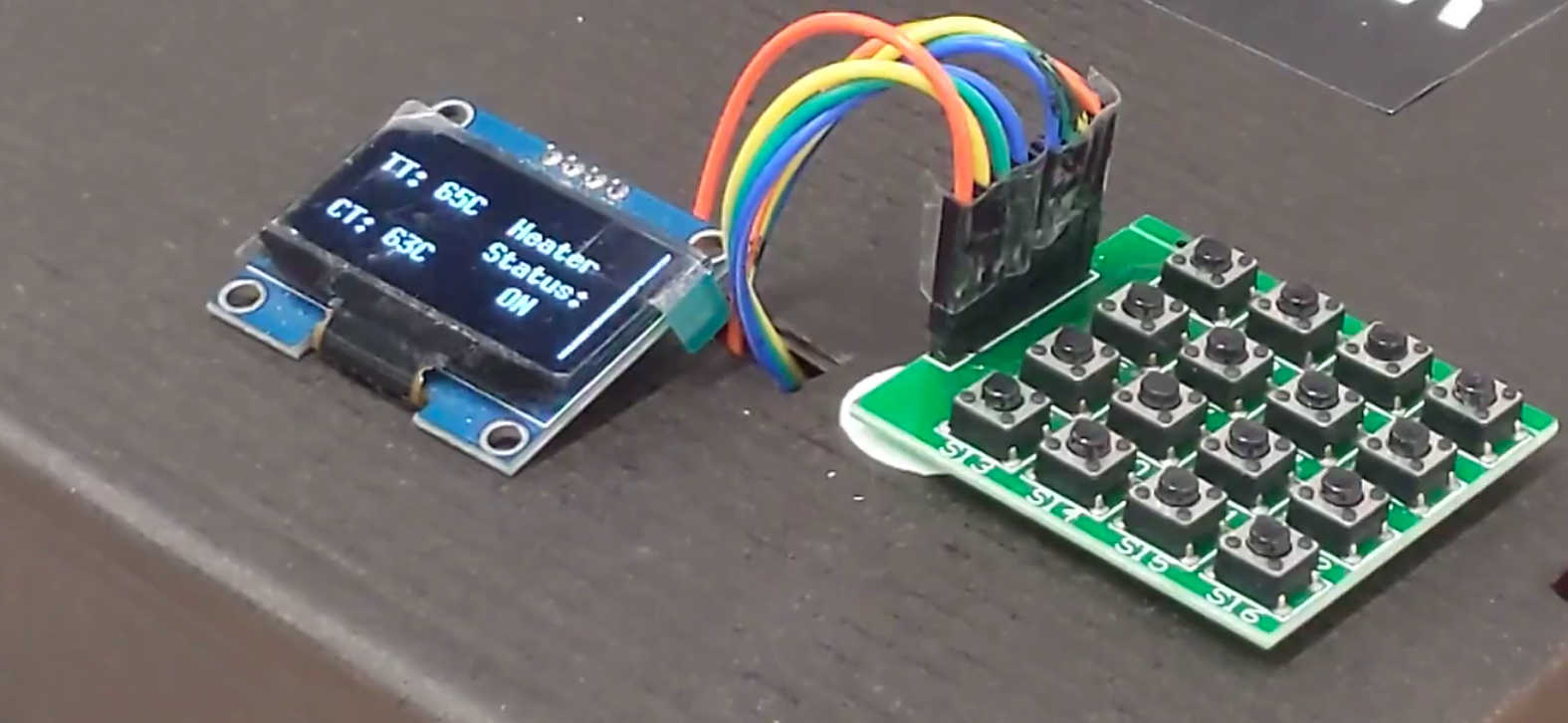

Test-Tube heater

A test-tube heater calibrated to heat up the contents of the test tube to specific temperatures and maintain it within +-2°C. Very small heating plates were used to heat up the test tubes at a reasonable rate so that the test tube doesn’t get damaged but it isn’t too slow either. A closed loop (PID) control system was set up so that the heaters respond to the readings received from the temperature sensor.

Spidfier

An integration of the tools mentioned earlier and more. A Minimum Viable Product that is capable of extracting the nucleic acid from fish samples in under 30 minutes.

While I cannot display the project on my website, you can still see the video of the working prototype on Youtube HERE.

Vayu / BREED

I had started off with data collection using IMUs. Later I became mostly involved with 3D Modeling, Design and Manufacture which encapsulated: Aerodynamics and Buoyancy-Weight distribution of the fish. We had designed the head and body of the fish such that it is aerodynamic and, has the proper buoyancy-weight distribution even while moving forward. In January 2020, Vayu achieved the GUINESS WORLD RECORD for being the fastest robotic fish.

ASRS 2.0

Automated Storage and Retrieval System for hand tools using the PRob 2R integrated with a custom electromagnetic gripper. The location of the tools will be determined with help of a camera integrated with a computer vision software. The robot determines the type of tool and stores/retrieves the tool to/from the allocated storage space. I was in charge of programming the robot and designing the gripper to pick up different tools.

ASRS 1.0

Automated Storage and Retrieval System for boxes on shelves. I was the team-leader for the project. The gripper arms were made from laser-cut Acrylic sheets with soft rubber to provide ample grip. A stepper motor with a rack and pinion was used to control the grips. There were an array of sensors which included IR sensor, ultrasound sensors and weight sensors to locate the box, place the arms the correct distance away and grip the box without damaging it. It was designed with redundancies to ensure the box does not get damaged.

Clearbot

Project Sponsored by the Gallant Ho Experiential Learning Fund. I worked in a team of 12 from different backgrounds and fields of study to design and test a trash collecting robot, to collect floating litter from the sea. A minimal viable product was tested in Bali, Indonesia.

Drag Reduction System

Worked with the Aerodynamics team to design an Active Drag Reduction System which would use single actuator to control the angle of two wings. They start off at two different angles with DRS turned off and switch to 15° angle (from the horizontal) with DRS turned on. It was only designed on Solidworks and was not manufactured due to budget and time constraints

Drone PID Control System

A PID control system set up using MATLAB (Simulink) to control a simulated drone.

Arcane Arcade

Worked in a team to create a videogame which was developed on Unity. It was targeted towards primary school children to promote recycling and other environmentally conscious behavior.

Drawing Tool (C#)

A simple drawing tool made using C# on Visual Studio. It could allow users to draw images with different colors and a button could allow the drawing to move and rotate.

RC Plane

An RC plane made using foam reinforced with carbon-fiber strips and a brushless DC motor. Two versions of the plane were made.

Irrigation System

A gearbox (for an irrigation system) designed using Solidworks for a school group project.

Miscellaneous

Line-Following Car

An Arduino-controlled car which ran using two rear brushless DC-motors and a trolley wheel up front. It used IR sensors to stay with the line and Ultrasound sensors to avoid collisions.

Flamenwerfer 1.0

A very simple single-hand-held “flamethrower”. A product of absolute boredom during COVID. Started off as a random 3D model but ultimately turned into stuff hacked together to set things on fire…

Open Ocean Camera (OOCAM)

Camera used to monitor marine life. I consulted with the team to help them design a housing for the electronics. It was designed to be modular, compact and user-friendly. 3D printed PLA was initially used to manufacture the part but later on it was 3D printed using Resin.

Door-Cam

I used an old Action Camera with a 3D printed housing to place it on the peephole and I used a power-bank to keep it powered on for longer. Currently working to improve the design and have the battery last longer.

Distance Visualizer (Arduino)

An OLED screen used to visualize distance between obstacle and the ultrasound sensor.

Ionic Blower

A crude construction that allows the device to generate “ionic wind” using high voltage terminals.

Inspired by the Youtuber Integza

Acrylic Knife

Got bored at a workshop and used the spare time to laser cut Acrylic sheets and attach them using Chloroform to make a knife. I later sharpened and painted for better aesthetics..